Painting an icon

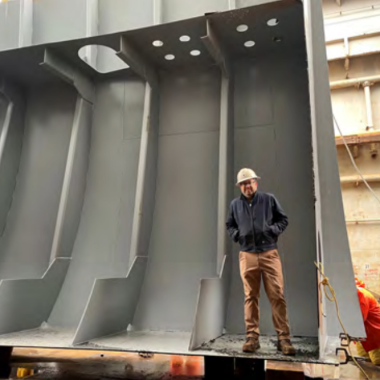

Battleship Texas, the last surviving dreadnought and WWII veteran, is being restored in Galveston with PPG coatings to match its original colors at Gulf Copper Shipyard’s Pier D.

Published 27 June 2024

_1.png)

Q. What has been PPG’s involvement with the USS Texas?

A. PPG has been involved with the Battleship Texas Foundation for many years, with the company’s formal involvement in the drydock refurbishment starting about three years ago. Before this, PPG had been engaged in smaller restoration projects by donating paint and volunteering time.

The current major refit of the USS Texas began with Gulf Copper Shipyard drydocking the ship in September 2022. PPG has a strong and positive relationship with Gulf Copper, making this collaboration a natural fit.

.png)

Q. Have you supplied all the coatings?

A. For the drydock phase, PPG supplied all the necessary coatings, initially focusing on the underwater hull. Future phases for the topside and other areas will involve additional coatings.

Q. Were the coatings supplied on a donation or paid-for basis (or a mixture of both)?

A. The Battleship Texas Foundation purchased the coatings for the current drydock phase. In the past, PPG has donated coatings and volunteered time for smaller restoration efforts.

Q. Can you provide detail on what preparation was carried out for the coatings on the different parts painted, i.e. grit blasted or water jetting, and to what standard? Was PPG involved in these decisions?

A. Based on coating surveys done prior to and during drydocking, PPG recommended gritting blasting the ship to Commercial Condition (SSPC-SP6). This included the current steel and any new steel added.

Q. Can you supply a list of the coatings and where they were used? When it comes to matching any colours – how was this achieved?

A. Solutions used include PPG SigmaWeld 199 primer, PPG Amercoat 240 epoxy, and PPG SigmaShield 880GF coating for the underwater hull, PPG PSX 700 polysiloxane, PPG SigmaShield 880GF coating for areas above the waterline, and PPG Amerlock 400 coating for the ship’s main guns. Specific coatings were chosen for different parts of the ship to ensure both protection and historical accuracy in appearance.

Q. Was any surface prep carried out between coats?

A. Occasionally, a freshwater pressure wash is completed between coats to ensure the surface is free of any surface contaminants.

Q. Was it sprayed or hand-painted?

A. Sprayed using an airless pump/gun. Brush and roll occurred for the touch-up of hard-to-reach angles/areas to ensure proper coatings coverage.

Q. How was PPG involved in each step?

A. PPG was involved in all pre-work meetings to ensure that surface prep and coatings specifications were followed. A large part of this oversight is performed by Louis Martinez, our Field Technical Service Rep. He has been invaluable in ensuring the job is completed correctly to ensure the Battleship Texas will be protected for years to come.

Q. I believe the ship has not been antifouled. Can you explain how the decision was made?

A. Antifouling was deemed unnecessary given the ship’s status as a stationary museum piece.

.png)

Q. When it comes to the other coatings selected – how were these decisions made?

A. Utilising PPG’s advanced colour-matching technology and historical colour charts, we ensured the ship’s appearance authentically reflected its original hue from its service in the World Wars. This precision in restoration showcases PPG’s commitment to colour excellence and historical accuracy.

“Coating decisions were based on the need for durability, historical accuracy in appearance, and protection against specific environmental challenges. We selected modern solutions while respecting the ship’s historical significance,” explains Josh Stinson, PPG Regional Sales Manager, Protective and Marine Coatings.

.png)

Q. Is there anything else you would like to add?

A. “The project has been a source of pride and honor for everyone involved, offering a chance to contribute to preserving a significant piece of history. Volunteers’ enthusiasm and personal engagement, including former military personnel and PPG team members, highlight the community’s strong connection to Battleship Texas and its legacy,” says Todd Moran, PPG Sales Representative, Protective and Marine Coatings.

“An especially touching aspect of this project was the involvement of ex-military personnel and local communities who participated in activities like cooking for visitors and signing the ship’s hull, creating a tangible and emotional link to the ship’s storied past. These acts of service and remembrance underscore the deep respect and reverence held for the Battleship Texas, further solidifying its place as a historical artefact and as a living testament to the sacrifices and achievements of those who served on it,” concludes Louis Martinez, PPG Technical Services Representative, Protective and Marine Coatings

Originally published in PCE International.