PPG FLOORING coating systems

If it's concrete, protect it with PPG

You can count on PPG for the right protection and the right technical support for your flooring application. View the PPG FLOORING Systems brochure and when you're ready, contact your PPG rep to design a system that’s right for you. Available in the US and Canada only.

Segments

PPG FLOORING coatings are designed with safety and durability in mind. Find your use case below to discover more details about our flooring solutions. Have questions? Use the contact form on this page to connect with a PPG flooring solutions expert.

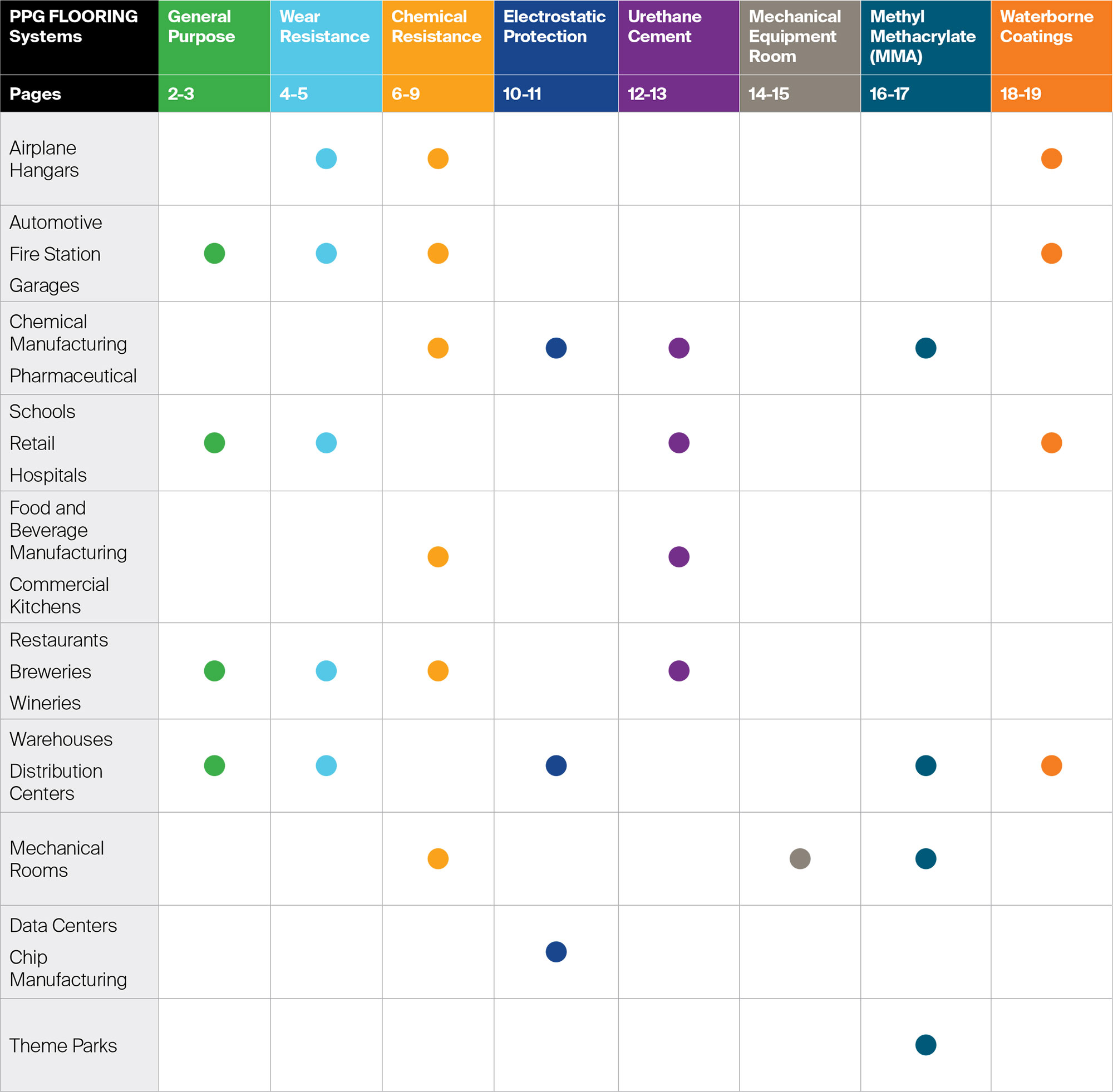

Selector Guide by Application/Environment

Flooring systems are available in a wide range of colors. Contact your PPG rep for more details.

All systems can be customized to achieve a variety of non-slip textures.

Flooring Segments

-

![Airplane Hangars]()

Airplane Hangars

• High reflectivity • Long-lasting for high traffic areas • Easy to clean • Guards against corrosion

-

![Automotive, Fire Stations, & Garages]()

Automotive, Fire Stations, & Garages

• Protects against oil, brake, & hydraulic fluids • Durable and long-lasting • Resistant to impact • Optional decorative flakes hide dirt and wear

-

![Chemical Manufacturing & Pharmaceutical]()

Chemical Manufacturing & Pharmaceutical

• Chemical resistant • Can repair badly eroded flooring • Provides impact and moisture resistance

-

![Data Centers & Chip Manufacturing]()

Data Centers & Chip Manufacturing

• Both dissipative and conductive systems available • Electrostatic protection

-

![EV Battery Plants]()

EV Battery Plants

• Protect against corrosion, high temperatures, and fire • Safeguard against ESD • Chemical and water resistant

-

![Food and Beverage Processing / Commercial Kitchens]()

Food and Beverage Processing / Commercial Kitchens

• Stands up to frequent washdowns • Resistant to impact and thermal shock • Enables you to return to service quickly

-

![Healthcare Facilities]()

Healthcare Facilities

• Easy to clean • Anti slip additives available • Self-leveling • Fast return-to-service

-

![Jails and Correctional]()

Jails and Correctional

• Self-leveling • Durable & long-lasting • Easy to clean • High reflectivity

-

![Laboratories]()

Laboratories

• Durable and long-lasting • Easy to clean • Stands up to high traffic & chemical spills • Non-skid

-

![Mechanical Rooms]()

Mechanical Rooms

• Easy to clean • Reflective • Self-leveling • Chemical resistant

-

![Restaurants, Breweries, & Wineries]()

Restaurants, Breweries, & Wineries

• Systems for both front of house and back of house spaces • Stands up to frequent washdowns • Self-leveling, self-priming, vapor-blocking, moisture-mitigating properties are available

-

![Schools, Retail, & Hospitals]()

Schools, Retail, & Hospitals

• Easy to clean & maintain • Long lasting • High wear top coat & decorative flakes • High reflectivity

-

![Theme Parks]()

Theme Parks

• Ultra-fast cure • Moisture-tolerant • Low VOC with tenacious bonding

-

![Warehouses & Distribution Centers]()

Warehouses & Distribution Centers

• High gloss • Easy to clean • Wear resistant

Flooring Systems

-

![General Purpose]()

General Purpose

• Self leveling • Seamless high-build coating • Moderate chemical and abrasion resistance

-

![Wear Resistance]()

Wear Resistance

• Extreme durability • Excellent scratch resistance • Chemical and stain resistance • UV stable

-

![Chemical Resistance]()

Chemical Resistance

• Excellent chemical resistance to acids, oils and chemicals • Epoxy, novolac and vinyl ester options • Thermal and mechanical shock resistance

-

![Electrostatic Protection]()

Electrostatic Protection

• Electrostatic discharge resistance • Chemical resistance • Extreme durability and abrasion resistance

-

![Urethane Cement System]()

Urethane Cement System

• Waterproofing membrane system with moisture resistance • Chemical, abrasion and impact resistance • Thermal and mechanical shock resistance • Multiple top coat options

-

![Mechanical Equipment Room]()

Mechanical Equipment Room

• Extreme resistance in high blast environments or chemical areas • Thermal shock resistance • Can be applied to new concrete

-

![Methyl Methacrylate (MMA)]()

Methyl Methacrylate (MMA)

• Excellent chemical and water resistance • Extreme durability in high water exposure environments • Rapid return to service

-

![PPG JOINT FILL Solutions]()

PPG JOINT FILL Solutions

• Self-leveling joint sealants for expansion and isolation joints • For filling for around machine pads • For standard exterior joints • Self-leveling joint fillers for control joints • Heavy vehicle or wheeled cart traffic • Pedestrian traffic • Forklift traffic • Heavy traffic and freezer thresholds

-

![PPG QUICK MENDER™ Concrete Repair]()

PPG QUICK MENDER™ Concrete Repair

PPG QUICK MENDER Repair Polymer

• Rapid repair and priming of concrete and masonry • Easily Polished • Low Viscosity for Excellent Penetration and Absorption • Low Temperature Application – as Low as -20 °F (-29 °C) • Can Be Mixed with Quartz Sand to Form Durable Polymer Concrete

-

![PPG QUICK MENDER X.O. Repair Polymer]()

PPG QUICK MENDER X.O. Repair Polymer

• For repair and patching horizontal concrete surfaces • Low odor, low viscosity • Rapid cure and return to service • Can be mixed with a wide variety of additives

-

![PPG Decorative Flakes and Metallics]()

PPG Decorative Flakes and Metallics

• Showroom quality floors made easy • Colorfast, UV stable pigments • Compatible with many chemistries • Odorless