PPG SIGMASHIELD™ MTC

High-performance coating system for dry cargo holds

Industry leading mechanical, thermal, chemical and anticorrosive properties at 2x100 microns.

PPG SIGMASHIELD MTC system is built on a unique coating technology that comprises a primer (PPG SIGMASHIELD PRIME) and topcoat (PPG SIGMASHIELD MTC).

This smart dry cargo holds system with a unique chemistry maximizes technical performance and offers a commercially sound solution for spot and full repairs while its robust properties make it the ideal solution for premium performance in new construction applications.

Benefits of the PPG SIGMASHIELD MTC system

- Unique coating technology maximizes technical performance at 2x100 microns

- Strong mechanical characteristics so that the coating can withstand the impact and constant abrasion of heavy, dense cargoes such as iron ore

- Outstanding chemical resistance so that the widest possible range of active cargoes can be carried

- Robust, long-term protection against corrosion

- Easy cleaning of the coating speeds up pre-loading inspections

Unique chemistry delivers best-in-class performance

The PPG SIGMASHIELD MTC system utilizes unique chemistry consisting of a pre-reacted amine in the hardener of the coating. This has the effect of "kickstarting" the curing of the coating and results in curing time and return to service that are among the fastest in the industry.

The Amine hardener has pre-polymers in the molecular design that boost the adhesive power of the binder system. This results in best in class anticorrosive properties when applied on steel. When applied on existing systems this offers enhanced surface tolerance.

The solid epoxy used in the binder matrix delivers a temperature tolerant system. From this outstanding mechanical, thermal and chemical resistance is provided as well as excellent surface hardness for easy cleaning and successful pre-loading inspections.

Our unique chemistry in the PPG SIGMASHIELD MTC system delivers optimized performance at two coats of 100 microns (4 mils). After application the vessel can resume service in just two days when transporting iron ore cargo and five days when carrying hot coal.

Maximum flexibility for cargo switching

The careful selection of inert raw materials in the formulation of the PPG SIGMASHIELD MTC system ensures that any unwanted chemical reactions are avoided and as such the system delivers excellent chemical resistance, allowing safe operation with all IMSBC cargoes and more.

Best-in-class abrasion and corrosion control

The system's excellent anti-abrasive and anti-corrosive properties extends the service life of vessels and is effective across a wide range of operating temperatures due to its high glass transition epoxy matrix. As a result, damage commonly caused by cargo settlement during vessel operation is minimized.

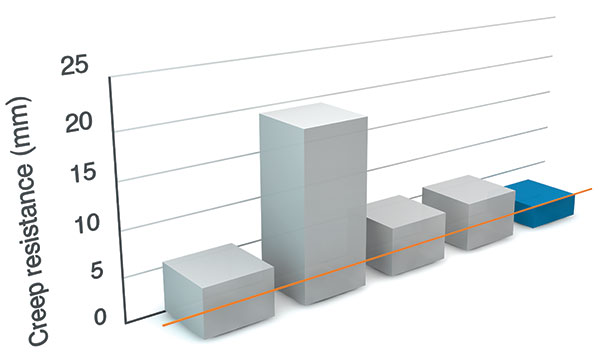

The surface wetting properties built into the Amine hardener provide excellent adhesion, anti-corrosion and creep resistance. So when inevitable mechanical damage eventually does occur, the area affected remains limited and so extends the service life of the coating.

The system has undergone extensive tests in controlled situations designed to mimic actual practice. When applied in enclosed environments containing various chemically active cargoes and subjected to temperature cycles in the presence of moisture, it was found that PPG SIGMASHIELD PRIME was the best in-class primer, exhibiting the smallest undercreep (similar to that of a water ballast tank coating system).

The below benchmark test results show that the PPG SIGMASHIELD MTC system outperforms competitor higher thickness coating systems.

Salt spray test of system after 2,240 hours