PPG PHENGUARD® 985

Setting a new standard in expanded chemical resistance for tanklinings

The trusted choice of professionals for over 50 years, the successful PPG PHENGUARD® range of tanklinings has further developed its line with the latest addition of PPG PHENGUARD® 985.

PPG PHENGUARD 985 utilizes a patent pending formulation that can be confidently applied in two or three coats, delivering extremely high chemical resistance to a wide range of aggressive cargoes – including higher temperature resistance for those containing fatty acids – without compromise.

PPG PHENGUARD 985 delivers...

1. Improved Performance

Market leading cargo-carrying resistance and significantly improved temperature window

PPG PHENGUARD 985 delivers outstanding chemical resistance to thousands of chemicals. Its particular value is in the protection it offers to over 300 different cargoes that are comprised of, or contain, fatty acids such as feedstock for biofuels e.g. used cooking oils.

Such highly aggressive cargoes can cause problems for land storage operators as feedstock solidifies at lower temperatures and needs to be kept at an elevated temperature in order to be efficiently stored, pumped and transported. However, the storage of such cargoes at these higher temperatures has a detrimental effect on the efficacy of the tanklining.

To combat this issue, PPG PHENGUARD 985 has been specifically designed to accommodate an extended temperature window for fatty acid distillates and similar cargoes. For example, operators can confidently allow tank temperatures up to 65°C/140°F for bio-diesel feedstock. If required, a loading or discharge temperature up to 70°C/158°F can be allowed for ten days of storage or alternatively up to 75°C/167°F for a maximum of two days.

2. Flexibility & Robustness

Enhanced performance with higher DFT tolerance in two or three coat applications

The unique formulation of PPG PHENGUARD 985 allows owners, operators and their painting contractors the flexibility to apply either two or three coats whilst having full confidence in the end result.

Customers choosing a two-coat solution (up to 2 x 160µm/ 6.3 mils) are now able to benefit from a higher dry film thickness allowance of readings up to 800µm/31.4 mils - in complex areas due to over-application.

As well as the initial saving on application cost gained by moving to a two-coat solution, this higher thickness tolerance also reduces the need for costly rework and additional time in case of over-application by painters.

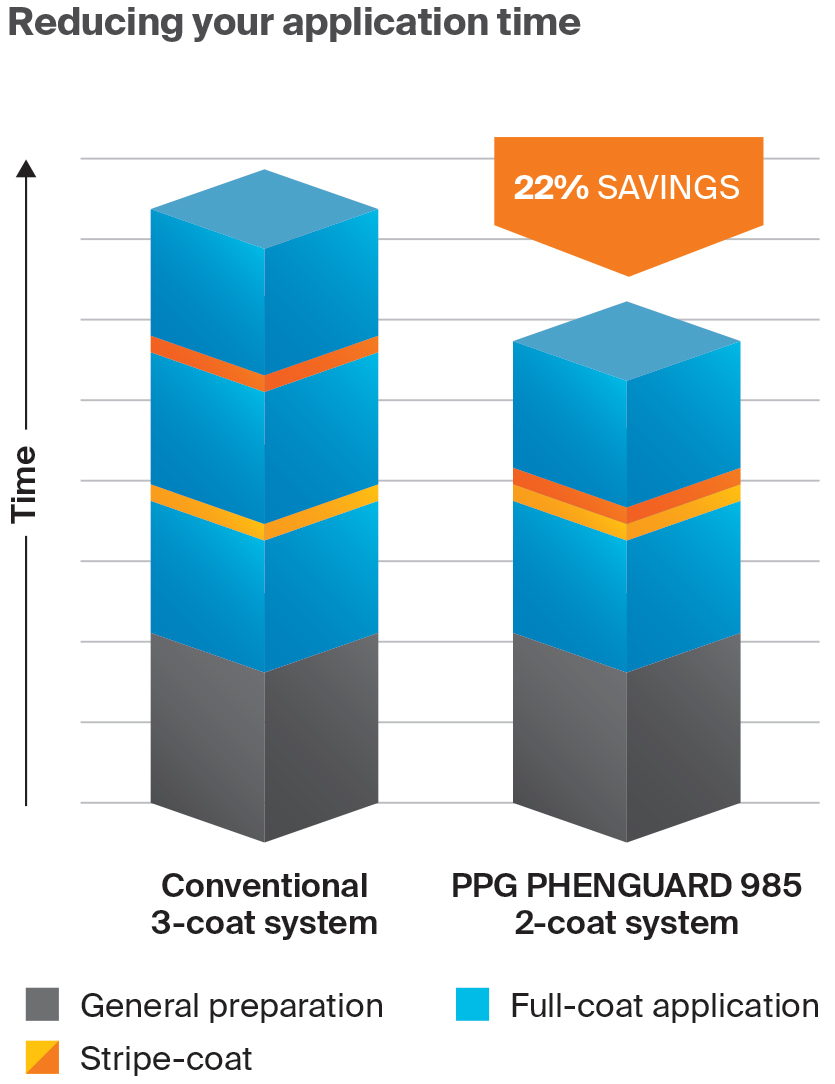

In tests and real-world application examples, it has been noted that application time can be reduced by up to 22% by using a two-coat solution - a significant saving in time and cost.

3. Health & Safety

Improved health and safety aspects via reduction in use of substances of concern

PPG takes a concerted and disciplined approach in developing sustainable products and processes. The new PPG PHENGUARD 985 has benefitted from this proactive approach with substances of concern having been reduced or totally removed without compromising its performance - including the minimization of crystalline silica in the filler package.

The high temperature tolerance of PPG PHENGUARD 985 also supports the fast emerging biofuels feedstock sector which uses recycled vegetable oils to produce environmentally friendly fuels; its formulation is ideal for the elevated temperatures that these sustainable energy sources typically require when being stored.

Such upgrades help support our customers with workplace safety, environmental impact and the achievement of their own sustainability goals.

Main features and benefits of PPG PHENGUARD 985

- Latest addition to the successful PPG PHENGUARD range, 50 year track record

- Premium solvent-based novolac phenolic epoxy tanklining

- High resistance to a wide range of (aggressive) cargoes

- Flexibility to specify and apply in two or three layers

- High DFT allowance

- Ideal for facilities that have dual refining processes switching from standard diesel to biodiesels

- Suitable for high purity, high value cargoes

- Suitable for all bio-fuels including feedstock

- Specifically bio-diesel feedstock up to 65°C/140°F

- Waste water in a broad pH range

- Hot water up to 100°C/212°F

- High operational flexibility (temperature/chemical resistance)

- Easy and quick to apply

- Easy to clean

- No risk of contamination between cargoes and therefore easy to switch between cargoes

- Improved health and safety aspects